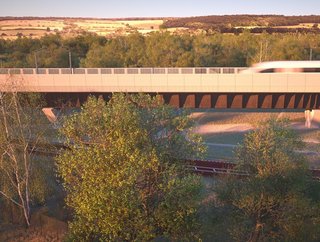

HS2 trials innovative technology to cut carbon by 10%

An industry first for construction, HS2 - Britain's high-speed rail line from London to the North West - has announced plans to develop a unique, automated civil engineering design process.

HS2 partners with Altair Ltd

Originally developed to design and optimise automotive and aerospace structures, HS2 is partnering with Altair Ltd to deploy its software tool - OptiStruct - to engineer some of the largest and most impressive structures on HS2.

The innovative programme will see the two companies reduce the carbon emissions of HS2’s viaducts by up to 10% as well as shrink its design time from a month to as little as an hour.

“Working with Altair as part of our Innovation programme demonstrates the benefits of applying its technology to building HS2, and the potential it offers in the long term as an integral tool to streamline structural designs and reduce embedded carbon by as much as 10%,” said Charlotte Hills, Senior Innovation Manager, HS2.

Traditionally, the design process to set a viaduct geometry and quantify the materials takes four weeks, Once set, there is almost never any opportunity to revise designs. By harnessing this intelligent technology - originally used to design components and assemblies within modern aircraft and automotive vehicles - to minimise the number of raw materials used, the technology provides engineers with design flexibility.

Taking into consideration the speed, frequency, and braking load of the high speed trains throughout its operational life, the technology runs millions of design iterations to produce an optimised design. By using materials in the most efficient way - while maintaining strength and longevity - the two expect to see up to 10% of embedded carbon reduced in the structures.

“Our innovation project with Altair is a game-changer. It gives engineers a tool to explore alternative designs that were not previously feasible due to time constraints,” said Tomas Garcia, Head of Civil Engineering Structures, at HS2.

“Altair’s design and optimisation technologies have been utilised across the industry for over two decades. However, we seldom see them deployed on structures as large as rail viaducts due to rigorous codes of practice. HS2 was determined to remove the barriers to adoption by integrating European Codes of Practice directly into the optimisation process. The resulting capability brings cutting-edge design and innovation to viaduct designers and opens further adoption in civil structure design,” said Martin Kemp, Senior Technical Specialist, Altair Ltd.

What is HS2?

HS2 is Britain’s high-speed rail line being built from London to the North West, totaling 170 miles. HS2 links the biggest cities in Scotland with Manchester, Birmingham, and London. The HS2 is the largest infrastructure project in Europe and the most important economic and social regeneration project in decades.

Integrating with new lines and upgrading across Britain’s rail system to deliver faster travel to major towns, US$29.2bn has been contracted into the supply chain with over 350 active sites between the West Midlands and London.